When it comes to using a generator, ensuring safety and efficiency is paramount. A crucial component of a generator’s safety system is the spark arrester. This article explores how to maintain generator spark arrester effectively to keep your equipment running safely and efficiently.

What is a Generator Spark Arrester?

A generator spark arrester is a device designed to prevent the emission of sparks and hot particles from the exhaust system.

These sparks can ignite flammable materials in the vicinity, which is particularly important when operating in areas with dry vegetation or other combustible materials.

By ensuring proper maintenance, you not only enhance the generator’s performance but also significantly reduce the risk of fire hazards.

Why is it Important to Maintain a Spark Arrester?

Proper maintenance of your generator spark arrester plays several vital roles:

- Safety: Prevents fires caused by ignited sparks.

- Efficiency: An unmaintained arrester can lead to decreased engine performance.

- Legal Compliance: Many areas have regulations requiring effective spark arresters.

- Longevity: Regular checks can prolong the life of your generator.

With these factors in mind, understanding how to maintain a generator spark arrester becomes critical.

How Often Should You Check the Spark Arrester?

It is recommended to check your spark arrester at least once a month if you use your generator regularly.

More frequent checks are advisable in environments with high debris or vegetation.

When learning how to maintain generator spark arrester, remember that seasonal changes can impact your maintenance schedule.

For instance:

- Fall and Spring: Leaves and debris can accumulate.

- Winter: Snow and ice can impair functionality.

- Summer: High temperatures may affect performance.

How to Perform Maintenance on a Generator Spark Arrester?

Maintaining a generator spark arrester involves several key steps. Follow these guidelines for effective maintenance:

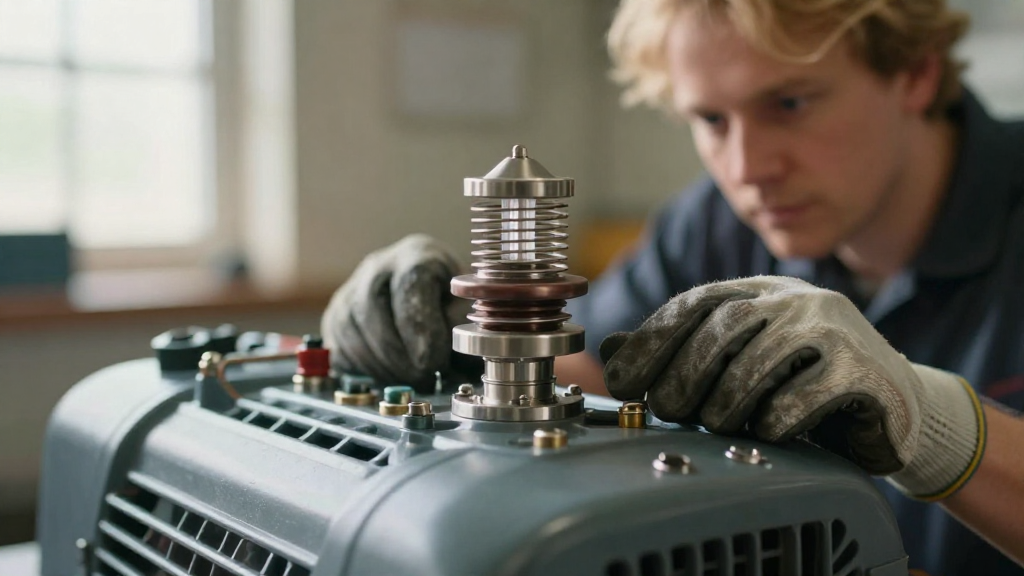

1. Gather Necessary Tools and Materials

Before starting, ensure you have:

- A screwdriver

- A brush (wire or soft-bristle)

- Protective gloves

- Protective eyewear

- A replacement spark arrester (if needed)

2. Turn Off the Generator

Before any maintenance, make sure to:

- Turn off the generator and allow it to cool.

- Disconnect it from any power source.

3. Locate the Spark Arrester

The spark arrester is typically positioned near the generator’s exhaust outlet.

Carefully read the manufacturer’s manual to locate it precisely.

4. Remove the Spark Arrester

Using your screwdriver, carefully unscrew the spark arrester from its position.

Keep all screws and parts in a safe place for reassembly.

5. Inspect the Spark Arrester

Look for:

- Clogs: Debris buildup can affect performance.

- Damage: Check for cracks or burn marks.

- Corrosion: This can indicate longer-term issues.

If you notice any significant damage, it may be time to replace the spark arrester with a new one.

6. Clean the Spark Arrester

Use a wire brush or soft-bristle brush to clean off any accumulated debris.

Make sure to remove:

- Soot

- Tar

- Other residue

Cleaning helps ensure the spark arrester functions properly and allows for better airflow.

7. Reassemble and Test

After cleaning, reattach the spark arrester back in its position.

Ensure all screws are tight and secure.

Reconnect your generator and run it briefly to ensure that everything is functioning properly.

What Signs Indicate Your Spark Arrester Needs Maintenance?

Recognizing signs that your generator spark arrester needs maintenance is vital for safety. Some indications include:

- Excessive noise: Unusual sounds may signal malfunction.

- Poor engine performance: If your generator runs roughly, it may point to a problem with the spark arrester.

- Increased emissions: A significant rise in emissions could suggest a clogged arrester.

- Visual damage: Any cracks or signs of wear and tear need immediate attention.

If you notice any of these issues, it’s time to consider how to maintain your generator spark arrester effectively.

How Can You Prevent Spark Arrester Blockage?

Preventative measures can save you time and effort in the long run. Here are some tips:

- Regularly inspect: Make it a habit to check periodically, especially after heavy use.

- Use clean fuel: Low-quality fuel can lead to increased deposits.

- Avoid operating near debris: Keep the area around your generator clear of combustible materials.

- Consider protective covers: During long periods of non-use, using a protective cover can minimize exposure to particulate matter.

What Are the Benefits of Properly Maintaining the Spark Arrester?

By understanding how to maintain generator spark arrester efficiently, you can unlock multiple benefits:

- Enhanced Safety: Reduces fire risk, keeping your surroundings safe.

- Improved Efficiency: A well-maintained spark arrester helps improve generator performance.

- Cost Savings: Proper maintenance prevents expensive repairs or replacements down the line.

- Environmental Responsibility: Lower emissions contribute to a cleaner environment.

What Should You Do If the Spark Arrester is Beyond Repair?

If you find that the spark arrester is damaged beyond the scope of simple maintenance,

you have two options:

- Replace It: Install a new spark arrester that matches the specifications of your generator.

Always refer to your generator’s warranty and documentation for the correct model.

- Consult an Expert: If you’re unsure about the maintenance or replacement process,

don’t hesitate to get professional help.

It’s always better to be safe than sorry when dealing with potentially dangerous equipment.

Conclusion

How to maintain generator spark arrester is crucial for the safety and efficiency of your generator.

Through regular inspections, cleaning, and proper handling, you can prolong the life of your equipment while ensuring safety.

By being diligent in your maintenance routine, you not only enhance performance but also contribute to a safer operating environment.

Remember, a little effort in maintenance can go a long way in preventing larger issues down the road. Stay safe and happy generating!