Generator cylinder head problems can severely affect the performance and lifespan of your generator.

In this article, we will explore what generator cylinder head problems are, their causes, symptoms, and how to prevent them. Understanding these issues will not only enhance your knowledge but also help in the maintenance of your generator.

What Is a Generator Cylinder Head?

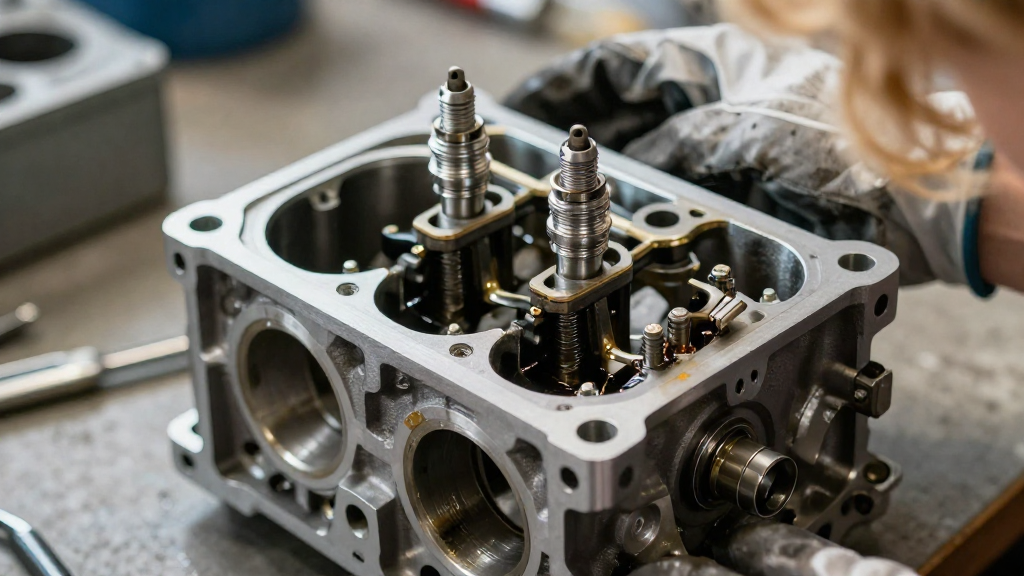

A generator cylinder head is a critical component of your generator’s engine.

It sits on top of the engine block and houses vital parts such as:

- Valves for the intake and exhaust

- Spark plugs or injectors

- Gaskets to ensure a seal between the cylinder head and engine

Generator cylinder head problems usually arise due to overheating, poor maintenance, or manufacturing defects.

These issues can lead to reduced efficiency, increased fuel consumption, and potential engine failure.

What Are the Causes of Generator Cylinder Head Problems?

Identifying the causes is crucial for prevention and troubleshooting. Here are the main reasons for generator cylinder head problems:

1. Overheating

Overheating is perhaps the most common cause of generator cylinder head issues.

When the engine runs excessively hot, it can lead to warping or cracking of the cylinder head.

Possible culprits include:

- Cooling system failures

- Low coolant levels

- Clogged radiators

2. Poor Maintenance

Neglecting regular maintenance can exacerbate wear and tear.

This neglect can lead to a buildup of carbon deposits in the combustion chamber, which affects the cylinder head’s function.

- Not changing the oil regularly

- Failing to replace air and fuel filters

These oversights can lead to premature cylinder head failure.

3. Poor Quality Fuel

Using low-quality or contaminated fuel can result in carbon buildup and increased engine wear.

Impurities in the fuel may lead to higher temperatures in the combustion chamber.

4. Manufacturing Defects

Sometimes, generator cylinder head problems can stem from inherent design flaws.

Manufacturing defects may not manifest until the generator is under load.

For this reason, it is essential to purchase equipment from reputable manufacturers.

What Are the Symptoms of Generator Cylinder Head Problems?

Recognizing symptoms of generator cylinder head problems as early as possible can save you from severe engine damage.

Here are some warning signs to watch out for:

1. Engine Overheating

If your generator is running hotter than normal, this is often a glaring symptom.

You may notice:

- Increased coolant temperature

- Steam or smoke rising from the engine area

2. Loss of Power

A generator with cylinder head problems may exhibit a decrease in power output.

You may find your unit is struggling to start or produce enough voltage for your needs.

3. Oil Leaks

Oil leaks around the cylinder head area are another potential indicator.

Look for:

- Wet spots or puddles beneath the generator

- Oil residue along the edges of the cylinder head

4. Rough Engine Operation

Changes in engine performance like knocking noises, rough idling, and misfires can also be attributed to cylinder head issues.

5. Excessive Exhaust Smoke

If you notice blue or white smoke coming from the exhaust, this could indicate coolant or oil burning in the combustion chamber.

How Can You Diagnose Generator Cylinder Head Problems?

Diagnosing generator cylinder head problems involves systematic inspection and testing:

1. Visual Inspection

Start with a thorough visual inspection.

Look for:

- Cracks or warping on the cylinder head

- Signs of oil or coolant leaks

2. Compression Test

Perform a compression test of the engine cylinders.

This will help you understand if the cylinder head is sealing properly.

Low compression readings can indicate a blown head gasket or warped cylinder head.

3. Cylinder Leak-down Test

A leak-down test can further diagnose issues by determining where the leak is occurring.

This test involves pressurizing each cylinder and checking for air escaping into the cooling system or oil pan.

4. Coolant System Pressure Test

Conducting a coolant system pressure test can reveal leaks in the cylinder head or gasket.

How Can You Repair Generator Cylinder Head Problems?

Fixing generator cylinder head problems can range from minor repairs to complete replacements.

Here are some common repair methods:

1. Resurfacing

If slight warping is detected, the cylinder head can often be resurfaced.

This involves grinding down the mating surface to create an even seal.

2. Gasket Replacement

If a blown gasket is causing issues, replacing it may rectify the problem.

Using high-quality gaskets is essential to avoid future failures.

3. Complete Cylinder Head Replacement

In cases of severe damage, it may be necessary to replace the entire cylinder head with a new or refurbished part.

4. Professional Help

Sometimes making repairs on your own can do more harm than good.

If you are not experienced with generator engines, it may be best to consult a mechanic.

How Can You Prevent Generator Cylinder Head Problems?

Prevention is always better than cure, especially concerning generator cylinder head problems.

Here are some proactive measures you can take:

1. Regular Maintenance

Establish and follow a maintenance schedule.

This should include:

- Changing the oil and filters

- Checking coolant levels regularly

- Inspecting hoses and belts for wear

2. Monitor Engine Temperature

Always pay attention to your generator’s temperature.

Overheating should not be tolerated; immediate action should be taken if the unit shows signs of excessive heat.

3. Use Quality Fuel

Invest in good quality fuel to prevent carbon buildup and wear on internal components.

4. Store Properly

If you need to store your generator, make sure it’s done correctly.

This prevents rust or component degradation.

Conclusion

Understanding generator cylinder head problems is vital for anyone relying on generator performance.

From causes to symptoms, along with effective repair and preventive measures, you now have a comprehensive guide at your disposal.

Knowing how to look after your generator can extend its lifespan and optimize its performance.

By being proactive and informed, you can keep your generator running smoothly, no matter what challenges come your way.