When it comes to the performance and efficiency of generators, generator sine wave quality explained is a topic that cannot be overlooked.

Understanding sine wave quality is crucial for anyone looking to invest in a generator or seeking to troubleshoot existing equipment.

What Is Generator Sine Wave Quality Explained?

The Basics of Sine Wave Output

A generator’s output can take various forms, but the most desirable is the sine wave.

Sine waves represent an electrical signal that alternates in polarity, creating a smooth, continuous waveform.

This smoothness is essential for several reasons:

- Reduced Harmonic Distortion: A pure sine wave has minimal harmonics, which means less strain on connected devices.

- Compatibility with Sensitive Electronics: Many electronic devices are designed to operate efficiently on pure sine wave power.

- Increased Efficiency: Generators with high sine wave quality provide better performance and durability.

In contrast, a generator that produces a non-sine wave output—such as a square wave or modified sine wave—may result in increased wear and tear on equipment, lower efficiency, and overall subpar performance.

Why Is Generator Sine Wave Quality Important?

When we dive deeper into generator sine wave quality explained, we uncover several important implications for generator users:

-

Device Compatibility:

– Many home and industrial appliances require stable, clean power for optimal operation.

– Devices like computers, medical equipment, and audio/video equipment depend on a pure sine wave for functionality. -

Operational Performance:

– Generators with higher sine wave quality produce consistent power outputs, enhancing performance and reliability.

– This is especially crucial for sensitive electronics that could fail or become damaged if the waveform is distorted. -

Longevity of Equipment:

– Poor sine wave quality can lead to overheating and increased wear on electrical components.

– This may shorten the lifespan of both the generator and the devices it powers.

How Can You Measure Generator Sine Wave Quality?

To determine the sine wave quality of a generator, several key metrics and tools can be used:

-

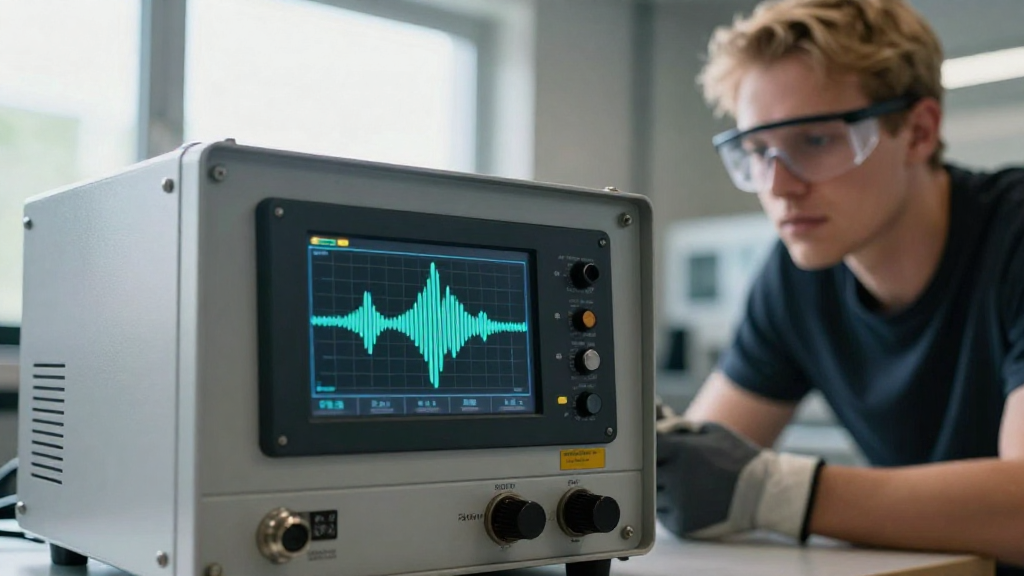

Oscilloscope:

– An oscilloscope can visualize the waveform produced by a generator.

– A clean, smooth sine wave with rounded peaks indicates good quality. -

Total Harmonic Distortion (THD):

– THD is a measure of the distortion present in the waveform.

– Ideally, THD should be below 5% for optimal sine wave quality. -

Load Testing:

– Performing load tests can help assess how well the generator maintains sine wave quality under varying power demands.

What Factors Affect Generator Sine Wave Quality?

Several variables influence generator sine wave quality:

-

Type of Generator:

– Inverter generators typically produce better sine wave quality compared to conventional generators.

– This is because inverter technology smoothens the output and keeps it constant, mimicking power from the grid. -

Load Conditions:

– The more balanced the load connected to the generator, the better the sine wave quality.

– Sudden changes in load can cause waveform distortion. -

Generator Design:

– The quality of materials, design architecture, and specifications all play a significant role.

– Premium generators often come with features specifically aimed at enhancing sine wave quality.

Are There Any Risks With Poor Sine Wave Quality?

Generator sine wave quality explained leads us to the potential risks associated with poor quality outputs:

-

Damage to Appliances:

– Devices powered by a poor-quality sine wave may experience overheating or failure.

– Motors may develop issues, leading to costly repairs or replacements. -

Inefficiency:

– Operating on a distorted sine wave can lead to increased energy consumption.

– This inefficiency can ultimately result in higher operational costs. -

Generator Strain:

– Inconsistent waves can put additional strain on the generator’s components.

– This may lead to premature wear and tear, reducing the generator’s overall lifespan.

How Can You Improve Generator Sine Wave Quality?

If you’re looking to enhance the sine wave quality of your generator, consider the following:

-

Choose Quality Equipment:

– Invest in an inverter generator or a high-quality unit designed for clean power output. -

Perform Regular Maintenance:

– Routine checks on fuel, oil, and filter conditions ensure optimal performance.

– Clean components and connections to reduce resistance and enhance functionality. -

Balancing Loads:

– Distribute electrical loads evenly to minimize stress on the generator.

– Avoid sudden starts and stops of heavy equipment while using the generator.

Conclusion: Why Understanding Generator Sine Wave Quality Is Vital

In summary, generator sine wave quality explained is essential for anyone using generators for home or professional applications.

Understanding the quality of a generator’s sine wave output is crucial for ensuring:

- Optimal performance

- Device compatibility

- Reduced risks of damage and inefficiencies

Whether you are investing in a new generator or maintaining a current one, prioritizing sine wave quality can save you both time and money in the long run. Always consider reputable brands and technologies that emphasize clean power output to get the most out of your generator.