Performing a generator valve adjustment procedure is a vital task to ensure your generator operates efficiently and reliably.

In this article, we will guide you through the steps involved in correctly adjusting the valves of your generator.

We will help you understand why it is essential and provide detailed guidelines on how to perform the adjustment correctly.

Why Is the Generator Valve Adjustment Procedure Necessary?

Ensuring the optimal performance of your generator begins with understanding the importance of valve adjustments.

What are valves, and why do they matter?

Valves in a generator’s engine play a crucial role in allowing air and fuel into the combustion chamber and releasing exhaust gases.

When these valves are out of adjustment, it can lead to several issues, including:

- Reduced performance: Affects your generator’s power output and efficiency.

- Increased fuel consumption: Poorly adjusted valves can lead to higher fuel usage.

- Potential engine damage: Over time, a lack of proper adjustment can result in severe engine wear or catalyst failure.

Regular maintenance, including a generator valve adjustment procedure, can help prevent these problems.

When Should You Perform a Generator Valve Adjustment?

How often should you perform the adjustment?

The frequency of your generator valve adjustment procedure depends on the type of generator and how often it is used.

Here are some general guidelines:

- For heavy use: Every 100 hours of operation or as recommended by the manufacturer.

- For moderate use: Every 200-300 hours of operation.

- For rarely used generators: At least once a year is advisable.

Always refer to your generator’s user manual for manufacturer-specific recommendations.

What Tools Do You Need for the Procedure?

What tools are essential for a proper adjustment?

Before you begin the generator valve adjustment procedure, gather the following tools:

- Wrenches or Socket Set: For loosening and tightening valve cover bolts.

- Feeler Gauge: To measure the gap between the valve and the rocker arm.

- Screwdriver: For adjusting screw-type valves.

- Torque Wrench: To ensure bolts are tightened to the manufacturer’s specifications.

- Shop Manual: Having the engine’s shop manual on hand is crucial for specific valve settings.

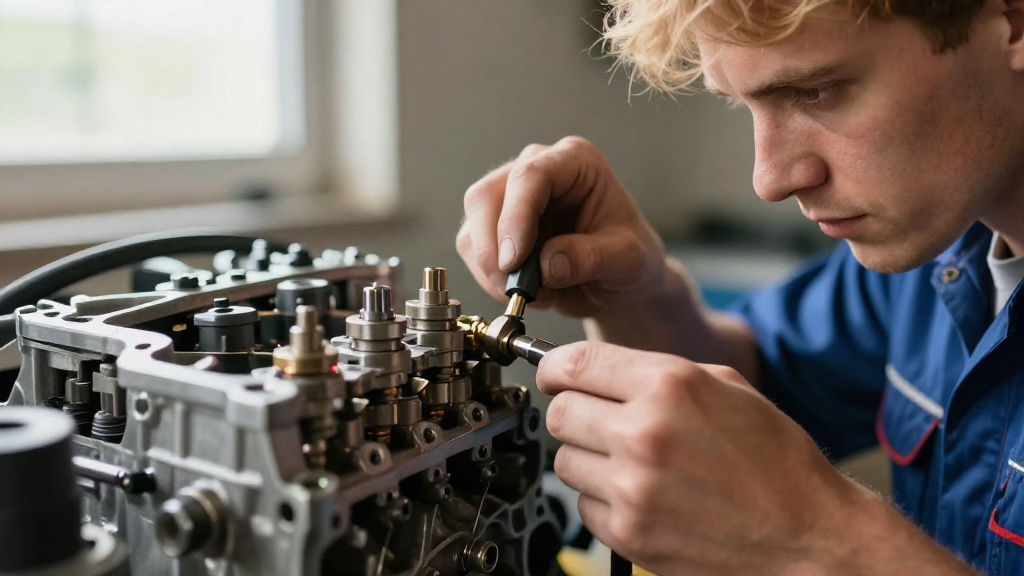

How Do You Perform the Generator Valve Adjustment Procedure?

What are the steps to adjust the valves?

Here’s a step-by-step guide to performing the generator valve adjustment procedure:

1. Prepare Your Generator

- Safety First: Disconnect the spark plug or power supply to the generator.

- Make sure the generator is on a flat surface and stable.

2. Remove the Valve Cover

- Use a wrench or socket to remove the bolts securing the valve cover.

- Carefully lift off the valve cover to expose the valves.

3. Determine Top Dead Center (TDC)

- How to find TDC?

- Rotate the flywheel until the piston is at TDC on the compression stroke.

- You can usually spot this by looking for timing marks or referring to the manual.

4. Measure Valve Clearance

- Using a feeler gauge, check the clearance between the valve and rocker arm.

- Refer to your manual for the proper valve clearance specifications.

5. Adjust the Valves

-

If the clearance is outside the specified range, you will need to adjust it.

-

For screw-type valves:

- Loosen the lock nut with a wrench.

- Use a screwdriver to turn the adjustment screw until you achieve the correct gap.

-

For shim-type valves:

- You may need to replace the shim with a thicker or thinner one based on the measurement.

6. Recheck the Clearance

- After adjustments, reinsert the feeler gauge to ensure the clearance is now correct.

- Repeat the adjustment if necessary.

7. Reassemble the Generator

- Once all valves are adjusted and confirmed, replace the valve cover.

- Tighten the bolts according to the manufacturer’s torque specifications.

8. Reconnect the Power and Test the Generator

- Reconnect the spark plug or power source.

- Start the generator and listen for any unusual sounds.

- Check for smooth operation and performance.

What Are the Common Mistakes During the Adjustment Procedure?

What pitfalls should you avoid?

When performing a generator valve adjustment procedure, here are some common mistakes to be aware of:

- Not following the manual: Always refer to the specific guidelines provided by your generator’s manufacturer.

- Skipping measurements: Proper measurements are essential; a single wrong adjustment can lead to significant problems.

- Neglecting safety precautions: Always ensure the generator is powered down for safety.

Conclusion: How to Excel at the Generator Valve Adjustment Procedure?

Mastering the generator valve adjustment procedure is essential for maintaining your generator’s efficiency and longevity.

By understanding the importance, preparing with the right tools, and following detailed steps, you can ensure your generator operates smoothly.

Regular maintenance, including valve adjustments, will save you time and money in the long run.

Now that you have this guide, you’re better equipped to tackle the generator valve adjustment procedure confidently.

Happy generating!