The internal combustion generator principle is a fundamental concept in the realm of power generation.

It involves converting chemical energy from fuel into mechanical energy, which is subsequently transformed into electrical energy.

How Does the Internal Combustion Generator Principle Work?

Understanding the internal combustion generator principle requires a grasp of several key components and processes.

-

Fuel Combustion:

– The process begins with the combustion of a fuel source, typically gasoline, diesel, or natural gas, within a confined environment known as a combustion chamber.

– When the fuel ignites, it releases a high-pressure gas that expands rapidly. -

Energy Conversion:

– This high-pressure gas exerts force on a piston or a turbine within a cylinder.

– The movement of the piston or turbine converts the energy from the gas into mechanical energy. -

Electricity Generation:

– The mechanical energy generated by the moving piston or rotating turbine is then transformed into electrical energy using a generator.

– In a generator, the mechanical motion spins a rotor inside a magnetic field, inducing an electrical current through electromagnetic induction. -

Output of Electricity:

– Finally, the electricity produced can be used for various applications, from powering homes to running industrial machinery.

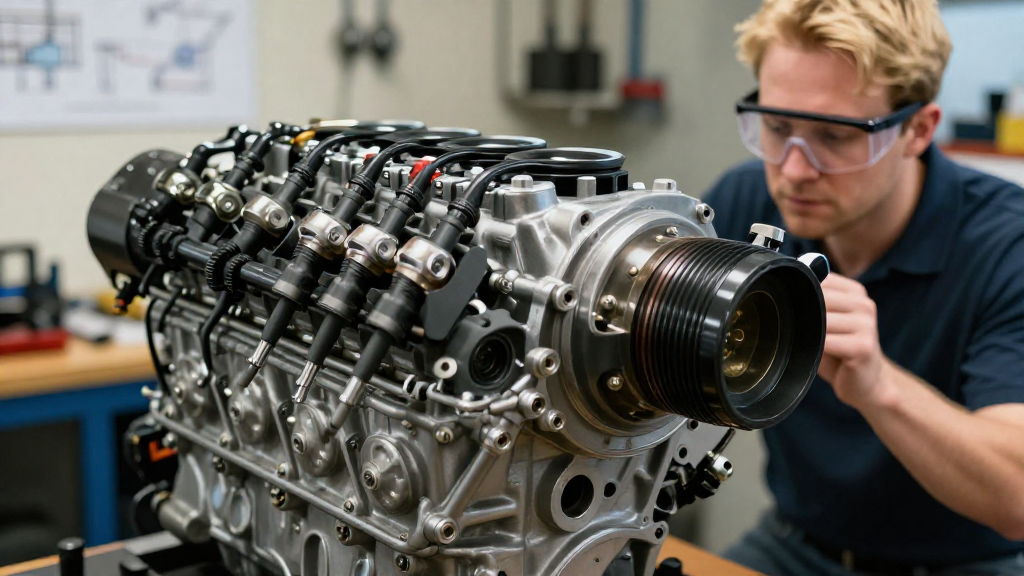

What are the Key Components of an Internal Combustion Generator?

To fully understand the internal combustion generator principle, it’s essential to recognize its main components:

- Combustion Chamber: Where the fuel burns and serves as the source of energy.

- Piston/Turbine: Converts the pressure from combustion into mechanical energy.

- Crankshaft: Transforms the linear motion of the piston into rotational motion.

- Generator: Produces electricity from the mechanical energy provided by the crankshaft.

- Fuel System: Supplies the appropriate mixture of fuel and air to the combustion chamber.

- Cooling System: Maintains operational temperatures to prevent overheating.

- Exhaust System: Removes combustion gases from the chamber efficiently.

Why Are Internal Combustion Generators Used?

The internal combustion generator principle offers several advantages that make it appealing for various applications:

-

Flexibility:

– These generators can run on a variety of fuels, providing flexibility to users based on availability and cost. -

Mobility:

– Numerous internal combustion generators are portable, making them ideal for remote locations where electricity is unavailable. -

Reliability:

– They have a proven track record and can function effectively in various conditions, making them a trusted choice for backup power. -

Efficiency:

– Many modern internal combustion generators utilize advanced technology to improve fuel efficiency and reduce emissions. -

High Power Output:

– Capable of producing substantial amounts of electricity, these generators are suitable for both residential and industrial use.

What is the Efficiency of Internal Combustion Generators?

Efficiency is a critical factor when assessing the internal combustion generator principle.

The overall efficiency of these generators typically ranges from 25% to 35%.

This percentage indicates how much of the energy in the fuel is converted into useful electrical energy.

Factors influencing efficiency include:

- Type of Fuel: Different fuels have varying energy contents.

- Maintenance: Well-maintained engines operate more efficiently.

- Load Conditions: The generator’s performance may vary based on load demands.

- Quality of Components: High-quality materials and design can lead to better combustion and energy conversion.

What Are the Common Applications of Internal Combustion Generators?

The internal combustion generator principle is widely utilized across various sectors, including:

- Residential Use: Providing backup electricity during outages.

- Construction Sites: Offering temporary power supply for tools and equipment.

- Remote Locations: Delivering electricity to areas without a power grid.

- Industrial Settings: Supporting operations with heavy machinery that demands substantial energy.

- Events and Festivals: Supplying power for lighting, sound equipment, and other amenities.

How Do Maintenance Practices Affect the Internal Combustion Generator Principle?

Regular maintenance is crucial to ensure that the internal combustion generator principle operates effectively.

Neglecting maintenance can lead to reduced efficiency, increased emissions, and costly repairs.

Here are some essential maintenance practices:

-

Regular Oil Changes:

– Keeping the engine lubricated helps prevent wear and tear on moving parts. -

Fuel Quality Checks:

– Using clean, high-quality fuel can prevent clogging and damage. -

Air Filter Maintenance:

– A clean air filter ensures optimal air intake for combustion. -

Spark Plug Inspection:

– Regular checks can ensure that the engine runs smoothly and efficiently. -

Cooling System Checks:

– Ensuring the cooling system is functioning effectively prevents overheating and prolongs generator life.

What Are the Environmental Considerations of Internal Combustion Generators?

While the internal combustion generator principle has many benefits, it also poses environmental concerns.

Combustion of fossil fuels releases greenhouse gases and other pollutants which contribute to climate change and air quality issues.

To mitigate these impacts, consider the following approaches:

-

Use Alternative Fuels:

– Biodiesel and natural gas are cleaner alternatives that reduce harmful emissions. -

Implement Emission Control Technologies:

– Technologies such as catalytic converters can drastically lower the emission of harmful gases. -

Optimize the Generator:

– Efficient operation reduces fuel consumption and emissions. Regular maintenance supports this goal. -

Explore Renewable Alternatives:

– Adopting solar or wind energy can provide clean, sustainable options without the downsides of combustion.

Conclusion

The internal combustion generator principle remains an integral part of our energy landscape, converting fuel into much-needed electricity for diverse applications.

Understanding its workings, components, applications, and maintenance is crucial for anyone involved in power generation.

With environmental challenges in mind, continuous innovation and responsible practices can help enhance efficiency while reducing the ecological footprint.

As we navigate the future of energy, a balanced approach utilizing the internal combustion generator principle alongside cleaner technologies will pave the way for sustainable power solutions.